8 Easy Facts About Plant Conveyors And Systems Shown

Table of ContentsGetting The Plant Conveyors And Systems To WorkPlant Conveyors And Systems for DummiesThe Main Principles Of Plant Conveyors And Systems The Best Guide To Plant Conveyors And SystemsThe Best Strategy To Use For Plant Conveyors And Systems7 Easy Facts About Plant Conveyors And Systems ShownSome Ideas on Plant Conveyors And Systems You Need To KnowWhat Does Plant Conveyors And Systems Do?

Issues with belt tracking can be brought on by abuse of the conveyor, its setting, and bad upkeep. Overlooking the belt can lead to costly fixings. Pneumatic Pressure Lots of conveying systems have pneumatic parts. As a part of maintenance, it is essential to make pressure changes as well as flow control and also regulatory authority adjustments.

555(a)( 2 ): Remote procedures need to have a stoppage switch at the motor. 1926. 555(a)( 3 ): Emergency situation quit buttons stop awakening of the system up until the emergency situation switch is reset to "ON". 1926. 555(a)( 4 ): Protective coverings as well as defense on screw conveyors are called for. 1926. 555(a)( 5 ): Overhead conveyors need to have safety coverings below the conveyor.

The Main Principles Of Plant Conveyors And Systems

0-2020, which covers the secure use of equipment as well as consists of various security devices that must be component of the setup as well as building and construction process. 1-2018: ASME B20. 1 -2018 consists of the needs for the design, building, maintenance, and procedure of a sharing system concerning dangers.

These will identify what kind of conveying is best fit for your manufacturing processes. Each conveyor includes its very own set of advantages and disadvantages that you must meticulously think about prior to making the decision. Here are seven basic sorts of commercial conveyors and also what you can anticipate from them.

3 Easy Facts About Plant Conveyors And Systems Described

At the exact same time, if material integrity is not of essence (such as in transferring waste), augers have few relocating parts and are very easy to maintain and also tidy. The foundation of an aero-mechanical system is the generation of a centrifugal pressure. This kind of conveyor includes a tube (typically made of steel) with an inside flowing rope.

Probably the most usual sort of conveyors, belt conveyor systems, have actually discovered their rightful place in almost every market. This system comes with sheaves (2 or even more) as well as a closed-loop (the conveyor belt) that revolves around them. Several pulleys in the system can be powered, relocating the belt in the best direction.

You can see them at flight terminals, carrying luggage, at dining establishments, carrying food (specifically sushi restaurants), at ski facilities, transferring individuals and their ski tools, and a lot more. A belt conveyor can be confined to stop contamination and loss of product, yet likewise be open if it is component of assembly lines - Plant Conveyors go to these guys and Systems.

About Plant Conveyors And Systems

As their name suggests, chain conveyors utilize an endless chain to carry product down an assembly line. The chain runs over gears at each end of the line, and it can have special accessories. One of the most usual application for chain conveyors is the activity of hefty loads large products that are really vast or very long (or both), such as industrial containers, grid boxes, and pallets.

Cord conveyors can move material in any direction you need vertically, horizontally, at angles, and around corners. These systems are additionally reasonably very easy to preserve due to the fact that they have detachable conveyor elements.

Take into account the dimension and height of the system contrasted to the flooring space of your center, as well as the type of material you desire to be shared. Loose material? While there are numerous different kinds of conveyor systems, they normally are composed of a frame that supports either rollers, wheels, or a belt, upon which materials move from one location to an additional.

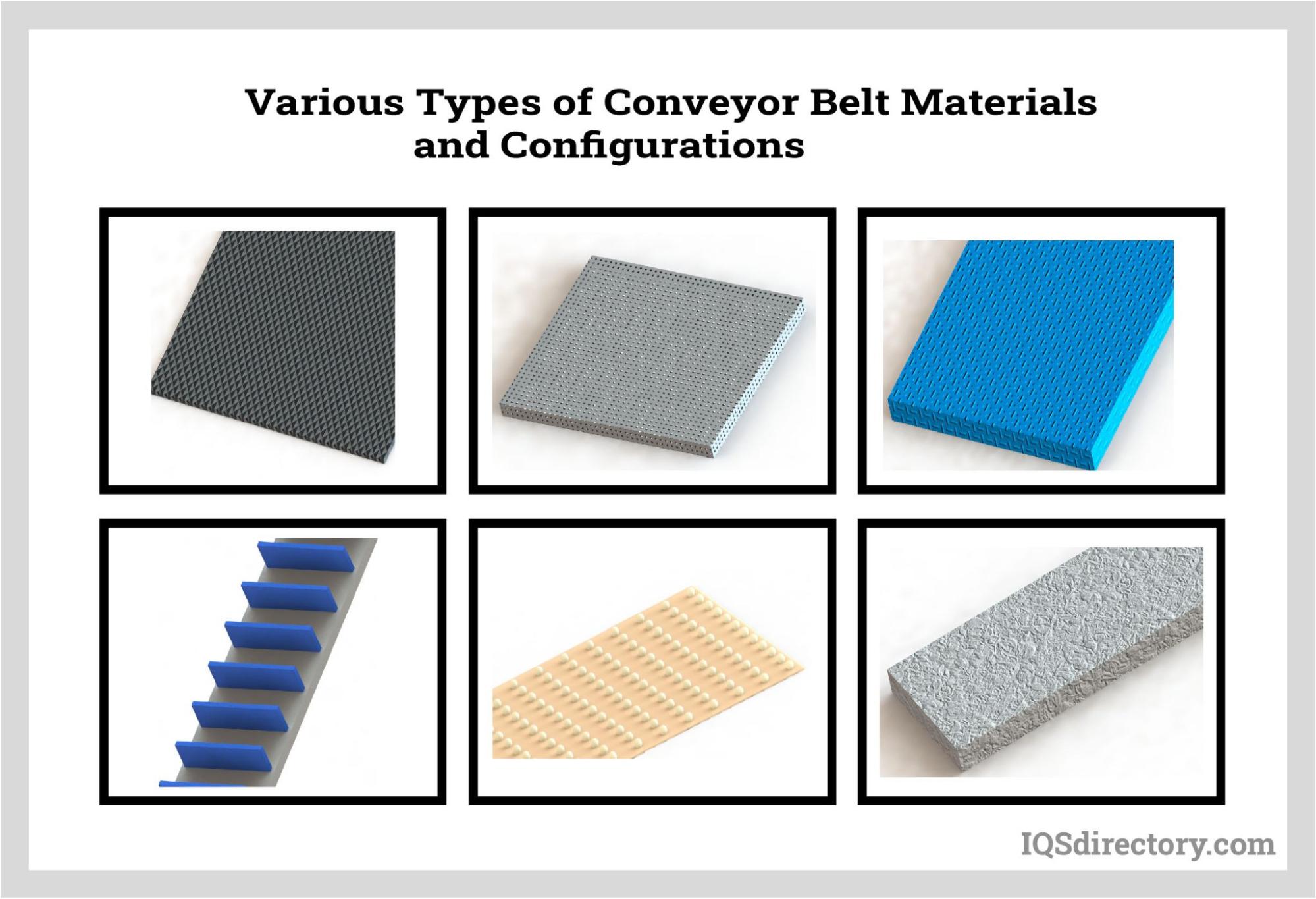

The conveyor belting is sustained by either a metal slider pan for light tons where no rubbing would certainly be used to the belt to cause drag or on rollers. Power is supplied by electric motors that utilize either variable or consistent rate decrease gears. The belts themselves can be made from countless products, which need to represent the conditions under which the belt will be operating.

Transporting a heavier Continue tons indicates a thicker as well as more powerful building and construction of conveyor belting product is required. Belt conveyors are commonly powered and also can be run at numerous rates depending on the throughput called for. The conveyors can be run horizontally or can be inclined too. Belt conveyors can be troughed for mass or huge products.

Little Known Facts About Plant Conveyors And Systems.

Secret specifications consist of the roller diameter and also axle center measurements. The rollers are not powered and utilize gravity, if inclined, to move the product, or by hand if mounted flat.

Cable conveyors can relocate material in any type of instructions you require vertically, flat, at angles, as well as around corners. They have reduced power expenses due to the fact that they work on electric motors of 7. 5HP or less. These systems are additionally fairly very easy to maintain since they have detachable conveyor components. The core feature of tubular wire conveyors is that they are exceptionally mild on the products.

Take right into account the you can try this out dimension and height of the system compared to the floor space of your center, as well as the kind of material you want to be shared. Loose material? While there are numerous different kinds of conveyor systems, they typically consist of a frame that supports either rollers, wheels, or a belt, upon which materials move from one place to another.

The conveyor belting is supported by either a metal slider frying pan for light tons where no rubbing would certainly be used to the belt to cause drag or on rollers. Power is supplied by electric motors that utilize either variable or consistent speed reduction equipments. The belts themselves can be made from various materials, which ought to represent the problems under which the belt will be operating.

Carrying a much heavier tons suggests a thicker and more powerful building of conveyor belting material is needed. Belt conveyors are usually powered and also can be run at different speeds depending on the throughput called for.

How Plant Conveyors And Systems can Save You Time, Stress, and Money.

Trick specs include the roller size as well as axle facility measurements. Roller conveyors are utilized mainly in material handling applications such as on packing docks, for baggage handling, or on production line among many others. The rollers are not powered and use gravity, if inclined, to relocate the product, or by hand if installed flat.